Strategies and instruments for improving the use of recycled materials

- Project team:

- Thematic area:

- Topic initiative:

Committee on the Environment, Nature Conservation and Nuclear Safety

- Analytical approach:

TA project

- Startdate:

2021

- Enddate:

2023

The final report of the TA project was approved by the Committee on Education, Research and Technology Assessment on 21 February 2024 and published as TAB-Arbeitsbericht Nr. 207 on 7 March 2024 (only in German). Key results of the report are published in the policy brief TAB-Fokus no. 44 and below.

How to improve the use of recycled materials in Germany?

Only a small proportion of the raw materials required in Germany are covered by recycled materials. The use of such recyclates can help to reduce dependency on raw materials, strengthen the competitiveness of the economy and protect the environment and climate. The TA project analysed the barriers to the use of recyclates and the strategies and instruments that could be used to increase their use.

At a glance

sprungmarken_marker_4124

All stages of the value-added chain must be considered

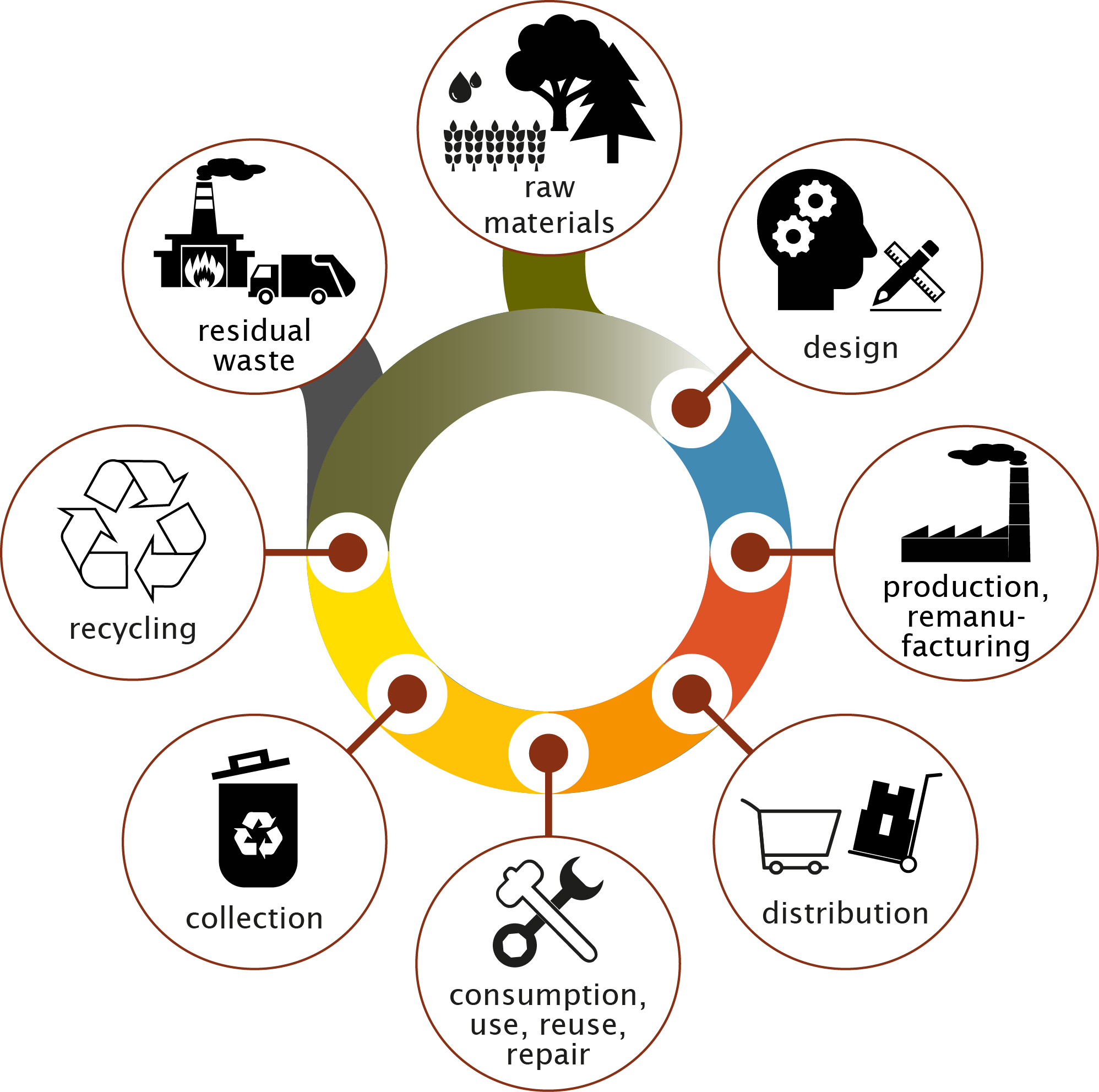

For an improved use of recycled materials, it is important to make adjustments along the entire product value-added chain – from recyclable product design, the collection of waste by type, technically high-quality recovery of recyclable materials to fair market conditions for the use of secondary raw materials. The chances of success for the recovery and use of recycled materials strongly depend on the material-specific properties of the respective waste stream and the resulting technical requirements for recycling processes. However, the legal and economic framework conditions that determine the intended use of recycled materials are also relevant.

Model of the circular economy

A differentiated look at product and waste areas reveals barriers and potential

Um die Anforderungen an den verbesserten Rezyklateinsatz differenziert zu beleuchten, wurden drei Produkt- bzw. Abfallbereiche im Detail untersucht: Kunststoffverpackungen, Elektro- und Elektronikabfälle sowie Bauabfälle. Ziel war jeweils eine Bestandsaufnahme der rechtlichen und wirtschaftlichen Rahmenbedingungen, die für die Gewinnung und die Vermarktung von Rezyklaten maßgeblich sind.

A differentiated look at product and waste areas reveals barriers and potential

In order to take a differentiated look at the requirements for improved use of recyclates, three product and waste areas were analysed in detail: plastic packaging, electrical and electronic waste and mineral construction and demolition waste. In each case, the aim was to provide for each of them the legal and economic framework conditions that are decisive for the extraction and marketing of recycled materials.

Plastic packaging

Plastic packagings (PE, PET, P, etc.) generated by private consumers account for approx. 40 % of plastic waste, but only a share of approx. 60 % of it has been recycled so far. In addition to the heterogeneous composition of plastic waste, it is above all the growing proportion of composite materials (e. g. multi-layer materials consisting of paper, plastic and metal) and the high degree of contamination due to product residues or labels, adhesives and paints that make high-quality recycling of plastics from packaging difficult.

A key obstacle is that collection via dual systems leads to heterogeneous waste mixtures that can only be separated by type with considerable effort. This is why high percentages of recycled materials are mainly found where specific collection systems ensure waste collection with a high degree of homogeneous sorting (e. g. PET deposit systems). Consideration should therefore be given to the extent to which such solutions can be extended to other packaging products. Other obstacles to high-quality recycling are the complex composition of packagings and the lack of transparency regarding product information. In this context, greater incentives for recyclable packaging design are needed, together with the systematic use of markers for labelling and the automatic recognition of plastics and packaging.

It would also be helpful to use modern sorting techniques to separate plastics according to type, material form and colour. However, the state of the art in recycling companies sometimes lags far behind what is technically feasible. The low or volatile prices of primary raw materials in particular are proving to be an obstacle to investment, which is having a negative impact on the economic viability of mechanical recycling. It is still highly uncertain whether chemical or bioenzymatic recycling offers ecologically and economically favourable alternatives to material recycling for selected types of plastic. It would therefore be important to improve the economic framework conditions for material recycling, for example by means of charges levied on plastic packagings that are predominantly made of primary plastic or by adjusting the licence fees for packaging.

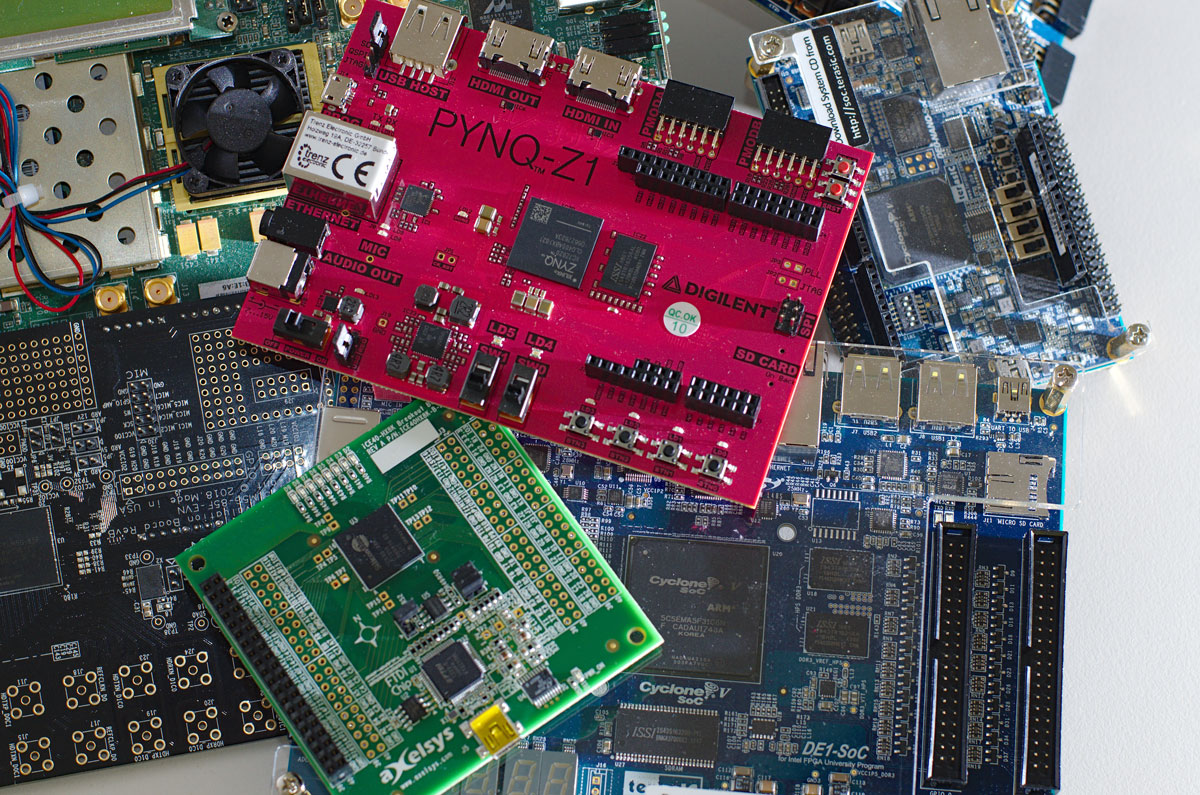

Electrical and electronic waste

Electrical and electronic waste is one of the fastest growing types of waste. In Germany, at the end of their useful life, more than half of all devices still end up outside the intended recycling and disposal channels. In addition, the small-scale design of products, which has hardly been designed for recycling so far, and the complex material composition of electronic waste are the main obstacles to high-quality recycling. As dismantling of the products is only possible to a limited extent, shredding of the materials results in the loss of low-concentration metals in particular. The subsequent recycling processes are based on metallurgical methods, are technically extremely demanding and are particularly complex for low-concentration metals. While comparatively high recovery rates are achieved for bulk metals (copper, aluminium, iron), they are usually marginal for the so-called critical metals (except for e. g. gold, silver and palladium).

On the one hand, improvements in recycling might be achieved through sorting technologies that enable a targeted, alloy-specific separation of material flows. On the other hand, for the recovery of critical metals such as rare earths – which cannot be carried out efficiently using existing metallurgical processes – further development of innovative metallurgical processes (e. g. biohydrometallurgy) is required. However, improving the recycling processes alone is not sufficient to increase the recovery rates of metallic materials. These processes rather must go hand in hand with improvements regarding product design and information (design for recycling) and collection systems (e. g. introduction of a deposit system).

Mineral construction and demolition waste

In terms of volume, construction waste is the largest waste group in Germany. Although the recycling targets have been achieved, high-quality recycling methods – in particular the use of recycled building materials in building construction – still play a minor role and in some cases lag far behind what is possible.

The main barriers include cheap disposal options (backfilling, etc.) and the fact that in practice construction waste – which is characterised by a very heterogeneous composition – is often not collected separately, as is actually required by law. Moreover, compared to primary raw materials, secondary raw materials are at a competitive disadvantage due to disadvantages in terms of price on the one hand and problems regarding acceptance on the other. Overall, this is why there is insufficient economic incentive for the operators of processing plants to produce high-quality recycled building materials at great expense.

In order to overcome these obstacles, it would be important to optimise the collection of construction waste (collection and processing according to type) on the one hand and to strengthen the purchase markets for recycled construction materials on the other hand, e. g. by specifically promoting the use of recycled construction materials for public procurement measures.

A look at the three waste areas shows clear parallels with regard to typical obstacles to successful recycling: These obstacles include a product design that is not designed for longevity and recyclability, inadequate waste collection as well as generally unfavourable economic and legal framework conditions that make recycling and the use of recycled materials unattractive. Against this background, steering measures are required to optimise the circular economy. For this purpose, new policy instruments are needed that go far beyond the existing instruments of waste legislation

Strategic policy options

A look at the three waste areas shows clear parallels with regard to typical obstacles to successful recycling: These obstacles include a product design that is not designed for longevity and recyclability, inadequate waste collection as well as generally unfavourable economic and legal framework conditions that make recycling and the use of recycled materials unattractive. Against this background, steering measures are required to optimise the circular economy. For this purpose, new policy instruments are needed that go far beyond the existing instruments of waste legislation.

Regulatory instruments

Regulatory instruments rely on direct control to influence societal behaviour by means of regulations, provisions, prohibitions, rules, norms or standards.

Regulatory instruments to increase the demand for recycled materials include legal product standards that define mandatory requirements for specific product groups, such as minimum percentages for the use of recycled materials (to increase the demand for secondary raw materials), requirements regarding product design (e. g. for dismantlability and recyclability) or the specification of criteria for the end-of-waste status of secondary raw materials (to release them from the waste status and legally recognise them as marketable products).

Economic instruments

In contrast to regulatory instruments, economic instruments have an indirect steering effect by attempting to influence behaviour by means of financial incentives. These include taxes and levies that apply to production.

Taxes on primary raw materials (or products made from these), for example, can compensate for any price disadvantages that products containing recycled materials might have compared to new goods made from primary raw materials. Other economic instruments focus on consumption. Examples of such instruments are excise duties (e. g. taxes on plastic bags or cement), levies/fees (e. g. on packaging or electrical and electronic equipment) or mandatory deposits. Measures to promote demand for products containing recycled materials within the framework of public procurement are also among the key economic levers.

Cooperative instruments

In order to achieve certain environmental goals, the state can also use cooperative instruments.

For this, the conditions under which secondary materials can be traded and used are defined on the basis of voluntary agreements with industry players. Examples include agreements on minimum percentages for the use of recycled materials considering currently available technologies and quantities of recycled materials. In this context, product groups and percentage levels are determined. Moreover, standards for a recycling-friendly product design can be established by means of voluntary agreements. The market players shall then implement the measures largely under their own responsibility. As a result, there is a good chance that they will accept and support the solution found.

In Germany, so far, the available repertoire of policy instruments has not yet been fully exploited. Traditionally, the main focus in Germany has been on innovations in the field of waste and recycling technology. A look at the instruments actually used in Germany shows that price signals (such as taxes on primary plastics or primary building materials) have been used very little so far. And if they have been used, they have hardly set any incentive (e. g. participation fees for packaging). To date, the potential of public procurement has also hardly been tapped. On the other hand, Germany is a pioneer with regard to deposit systems for the beverage sector, which were introduced in the early 2000s. However, the mandatory deposit was not extended to other products.

Various measures can be taken to increase the use of recycled materials:

- stricter requirements for the design of recyclable products, including the definition of binding

- information and labelling obligations,

- clear regulations regarding the end-of-waste status of reprocessed secondary materials,

- minimum quotas for recycled materials and

- public procurement to strengthen the demand for recycled materials.

New indicators needed to realistically measure progress

In order to develop sufficient incentive effects, it is of central importance that instruments interact well with each other and are designed to work together. Currently, however, there are still considerable gaps in our knowledge as to whether the instruments applied have actually had the desired effect. In order to monitor the incentive effects of policy measures specifically aimed at improving the use of recycled materials, statistics on the quantity of secondary raw materials actually used – broken down by material/product group – are required above all. So far, however, there are no meaningful indicators for this issue. The success of the circular economy is primarily assessed on the basis of recycling rates, which – however – do not have any significance with regard to the actual quantity of secondary raw materials used. This is why it would be necessary to develop suitable indicators, such as quotas for substitution or for the use of recyclates, which measure the success of the circular economy or the actual use of recycled materials more realistically.

Integration into an ambitious overall strategy

When developing strategies and instruments to improve the use of recycled materials, it must be borne in mind that recycling and the use of recycled materials are only one element of a resource-conserving circular economy. According to the guiding principle of waste hierarchy, material recycling should have a lower priority than waste prevention and reuse. This means that measures to improve the use of recycled materials should be harmonised and combined with other circular economy strategies, such as a long service life for products and materials or a right to repair.

The associated fundamental change to the economic model is an extremely challenging task, which will primarily require politicians to manage and set the framework. Very specific, small-scale measures are needed that are tailored to the relevant waste streams, but which must be combined to form a coherent, consistent whole. All of this can only be achieved within the framework of a broad, strategic policy approach in which the transformation to a circular economy is not seen as an exclusively environmental policy issue, but in which all departments are called upon, e. g. by means of sector targets. The National Circular Economy Strategy, which is currently being developed, offers the opportunity to develop a consistent, ambitious overall strategy for the circular economy in Germany that is based on binding targets and clear indicators and involves all stakeholders in order to bring about systemic change.

Downloads

|

TAB-Fokus no. 44 Our policy brief TAB-Fokus offers a compact overview of the content and results of our TA analyses on four pages.

TAB-Fokus Nr. 44 (in German) |

|

TAB-Arbeitsbericht Nr. 207 (only in German)

|

In the media

- 3sat.de/nano (27.11.2024). Dem Plastikwahnsinn ein Ende setzen. Neue Recycling-Politik gefordert, ab Min. 8:35 ( (u.a. mit Pauline Riousset)

- telepolis.de (12.03.2024), Gebühren, Steuern, Verbote: Wie weit soll der Staat beim Recycling eingreifen?

- taz.de (08.03.2024), Zu viel Müll aus Joghurtbechern. Recycelte Rohstoffe sind wichtig für die Kreislaufwirtschaft, aber selten vorhanden. Ein Bundestagsbericht zeigt, was es für deren Förderung braucht.

- deutschlandfunk.de (07.03.2024), Einsatz von Recyclaten bei Kunststoffen, Interview mit Henning Wilts vom Wuppertal Institut anlässlich der Veröffentlichung des TAB-Berichts zu Strategien und Instrumenten für einen besseren Rezyklateinsatz.

- faz.net (07.03.2024), Was soll aus dem Plastikmüll werden? Verfahren, die Kunststoffe in ihre chemischen Einzelteile zerlegen, könnten die Recyclingquote steigern. Dies erfordert allerdings mehr Forschung - und Anreize, etwa durch eine Plastiksteuer.

- sciencemediacenter.de (07.03.2024), Einsatz von Rezyklaten bei Kunststoffen: Helfen neue Recyclingverfahren? Das SMC hat Forschende gebeten, die im TAB-Bericht vorgeschlagenen Instrumente zum Kunststoffbereich mit Fokus auf chemische und bioenzymatische Verfahren einzuschätzen und sie befragt, wie die sogenannte Plastiksteuer sinnvoll auszugestalten wäre.

Further reading on the topic

|

Themenkurzprofil Nr. 69

|

|

|

Themenkurzprofil Nr. 35

|